Optimisers vs. Microinverters: Comparing module-level optimisation

.png)

You’ve got a complex, shaded installation and you need panel output optimisation. What do you do? Do you rely on the improving technology of modern panels, opt for optimisers, or go big on microinverters? We’ll take a look at the pros and cons of each module optimisation technology so you can make the right choice for your installation.

Panel technology

It used to be the case that a shaded panel reduced the output of the whole system significantly, potentially leading to output power losses of up to 95% and risking permanent damage to your panels. This is no longer a common problem since the advent of bypass diodes which take the underperforming panel(s) out of the equation, allowing the others to continue generating power. Most modern panels utilise bypass diodes, and therefore suffer far less underperformance from strong or localised shading.

However, this technology still struggles when the shading is only light or scattered, or is a consequence of dust or debris on the panels. This is because most panels are fitted with 3 bypass diodes, each covering a third of the panel’s area. They only activate when shading reaches around 20% of the surface area the particular bypass diode is responsible for. So, if only 15% of the whole panel is shaded, and this shading is spread out over all 3 sections, none of the diodes will activate and there will be a significant drop in power output over the whole system.

Optimisers

In this situation, many installers will reach for PV optimisers to squeeze as much efficiency out of shaded or complex roofs, since they are able to intelligently optimise the output of each individual panel using maximum power point tracking (MPPT). Optimisers provide this MPPT within DC-DC architecture, using specially designed circuitry to increase (boost) or decrease (buck) the output of each panel so that, cumulatively, the total power output (W) is as high as possible. This technology can deliver on average a 6.6% improvement in efficiency in non-extreme shading situations. They are often used as a budget-friendly measure to combat shading-related inefficiencies, and also can be used to increase ECO4 grant funding. For example, Instagen 435W panels with Tigo optimisers and a CCA TAP unlock the highest ECO4 innovation measure uplift of 45%.

But are they always the best solution? Optimisers introduce some extra power losses to the system: Firstly, their own efficiency ranges from 96-97.5% in real-world scenarios and they require some energy to stay on, representing between 2-4% of the total system’s production in power losses. Secondly, the additional cabling required in optimiser installations (approximately 2.7m of extra cabling per optimised panel) leads to power loss due to resistance of about 1% in addition to the above. Finally, systems with optimisers still require a string/hybrid inverter, and although these typically have very high efficiency ratings of around 99%, that still introduces another 1% loss into the equation. The total? About 4-6% of power generated by the system will be lost. This figure stays fairly consistent regardless of the specific installation, but the actual benefit of the optimisers can vary quite a lot.

There are too many variables to go over all of them here, but in general optimisers work at their best in scenarios where the shading is not too extreme and stays relatively consistent or predictable. When the shading comes from multiple and/or complex panel orientations, changes rapidly, or is a consequence of early morning or late evening shadows then they struggle when compared with microinverters.

Microinverters

Microinverters are another type of module level power electronic (MLPE) that optimises panel output using MPPT and converts the DC generated by the panels directly to AC on-module. They are an up-and-coming challenger to optimisers that excel in the right situation.

In terms of efficiency, they don’t have the same amount of loss points as optimisers do (long cabling, traditional inverter), which means they can boast a 2-5% improvement in final power output numbers over systems with optimisers unless there is almost no shading, in which case a simple traditional inverter system is the most effective of all three options.

Microinverters are generally superior in optimising shaded installations, and where they really excel is if the panels are configured in multiple cardinal orientations. Because they convert the DC to AC directly on-module and have incredibly rapid MPPT sampling, they can maximise the output of each panel individually, whereas optimisers have some level of system-wide MPPT limitation and struggle to cope with panels in different orientations.

Microinverters also have far lower startup voltage requirements (between 20-30V) than systems with optimisers, which require at least 60 and usually closer to 200V to be generated by the panels to begin working. This means that microinverters can capitalise on the early morning and late evening gains.

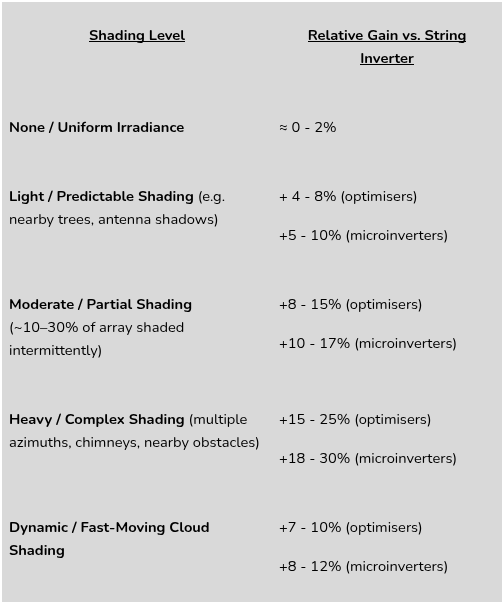

Figure 1. Comparison of optimisers vs. microinverters in different shading scenarios

As we can see, microinverters are superior in almost every shading scenario due to a combination of faster MPPT sampling and high efficiency. But what about ease of installation? Any build that uses MLPEs will involve more components, but that’s only part of the picture since the cabling, connectors, and design of the components have a significant impact on ease and speed of installation.

Installation

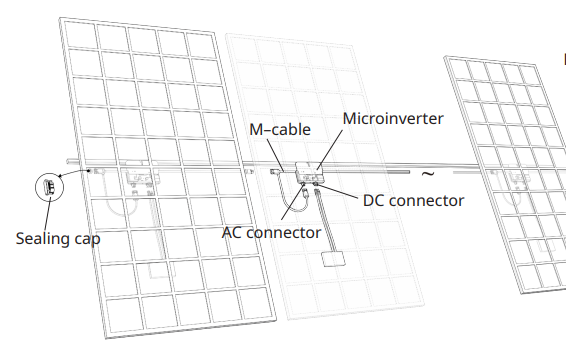

Compared to installing optimisers, microinverters save you approximately 30% labour time on an average 5kWp build - that’s about 2 hours faster than optimisers! This is possible partly because microinverters are very quick to install - much more straightforward than optimisers, since they are linked up via plug-and-play cables that take seconds to connect, and do not require the DC wiring layout process that optimisers do. On top of this, there’s no additional inverter wiring or configuration process required since all the inverter wiring is completed by a couple of plug clicks. No need to worry about getting the DC-to-inverter wiring perfect since there quite simply isn’t any. Have a look at the picture below to see what this looks like, and compare it to the 2.7m of extra cabling required per panel when fitted with an optimiser!

Microinverters also make system design more flexible and easier to scale. Installers can add or reposition panels without redesigning entire strings, which is especially useful for irregular or partially shaded roof layouts. Optimiser systems often will require a new traditional inverter to match the new power output if you add additional panels later on, although you can add panels without necessarily needing to add an optimiser as well.

Figure 2. Atmoce microinverter connection diagram

If this sounds too good to be true, let’s lay it out. Say you’re designing a 12-panel, 5kWp residential system and are considering both optimisers and microinverters:

Optimisers and inverter

- Mount optimisers: 12 × 5 min = 60 min

- Mount panels: 12 × 10 min = 120 min

- DC wiring/string layout = 90 min

- Inverter mounting/wiring/configuration = 90 min

Commissioning/pairing = 30 min.

Microinverters

- Mount microinverters: 12 × 6 min = 72 min

- Mount panels: 12 × 10 min = 120 min

- AC trunk wiring = 45 min

- Commissioning (gateway discovery) = 30 min

That’s roughly 2h saved on a 6–7 h job, or a 25–30 % faster installation time.

Cost

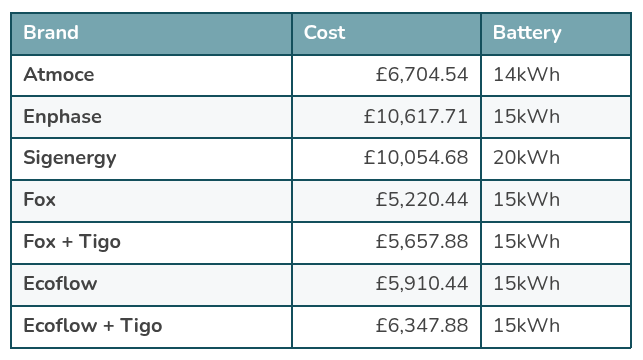

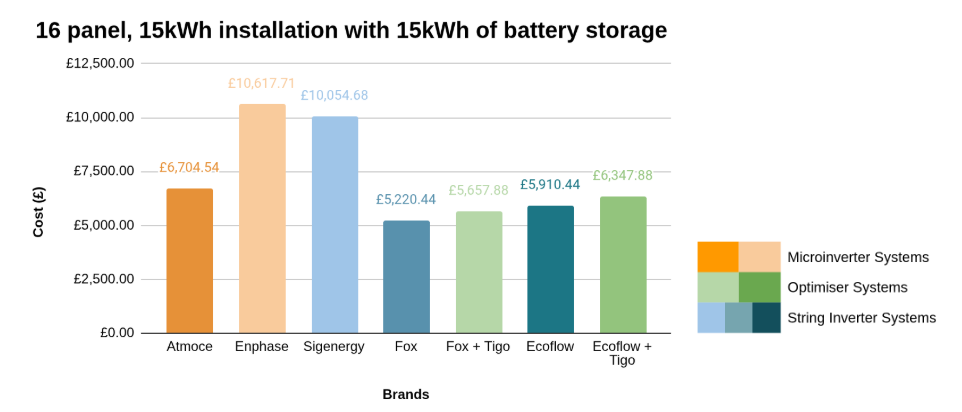

That’s all well and good, but aren’t optimisers cheaper? Homeowners want value for money, after all. Well, we think this might be a false economy. Let’s have another look at some numbers:

Figure 3. Comparison of common installation design costs

Graph 1. Comparison of common installation design costs

Reliability

Microinverters offer incredibly impressive reliability by creating redundancy in the system - even if one fails, the others still function fully which means the rest of the panels continue producing energy at their normal rate. Some people worry that having to install one microinverter per panel, leading to more total components in the build, will mean that the system is more likely to fail. Actually, this is far from the truth: a failing microinverter is incredibly uncommon! They have a 0.055% failure rate, 16 times lower than string inverters.

Safety

Microinverters operate at low-voltage AC rather than high-voltage DC, significantly reducing electrical risk and meaning dangerous high voltage DC stays outside the home. This both enhances safety during installation and maintenance and can also speed up on-site work by minimising the need for high-voltage safety precautions.

Summary

We’ve written more about the benefits of microinverters here: (we think they’re great) so we’ll leave some of the more technical details out for now. We think the main points are that microinverter systems outperform optimisers in almost every scenario, are safer and easier to install, and finally are available at a competitive pricing compared to optimiser systems. When you consider microinverters’ reliability and excellent warranty (especially given that string/hybrid inverters are the most likely component to fail in a PV system) it’s easy to see why microinverters are an excellent choice for homeowners as well as installers. The fact that microinverters connect your solar energy generation to a whole-home energy management ecosystem that can be managed seamlessly through an app (e.g. Atmozen from Atmoce) is a cherry on top.

Have a look at the range of Atmoce and Enphase microinverters at Midsummer.